Tungsten alloy pin| Tungsten wire for sale

| Payment Type: | T/T, Can be negotiated |

| Incoterm: | FOB,CIF,FCA,EXW,Express Delivery |

| Min. Order: | 100PCS |

| Transportation: | Ocean,Air,Express |

Attributes

Model No.: JDTG-TP-046

Brand: ZZJD

Place Of Origin: China

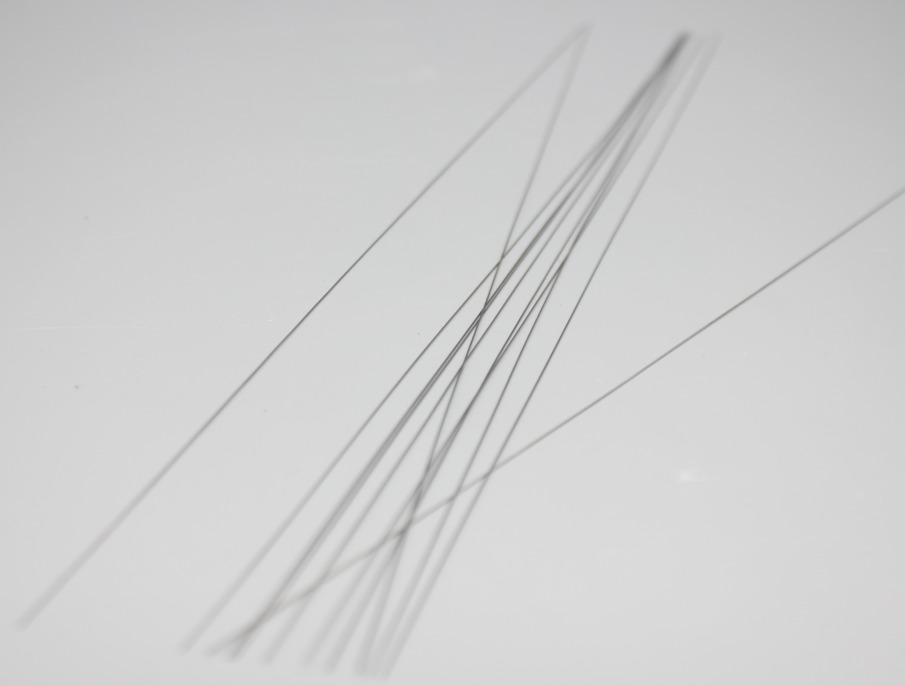

Size: φ0.25mm

Material: tungsten

Density: 17.5~19.1g/cm³

Length: Support customization

Lead Time: 15~20 days

PACKAGING & DELIVERY

Selling Units : Piece/Pieces

Package Type : Standard export packing

DESCRIPTION

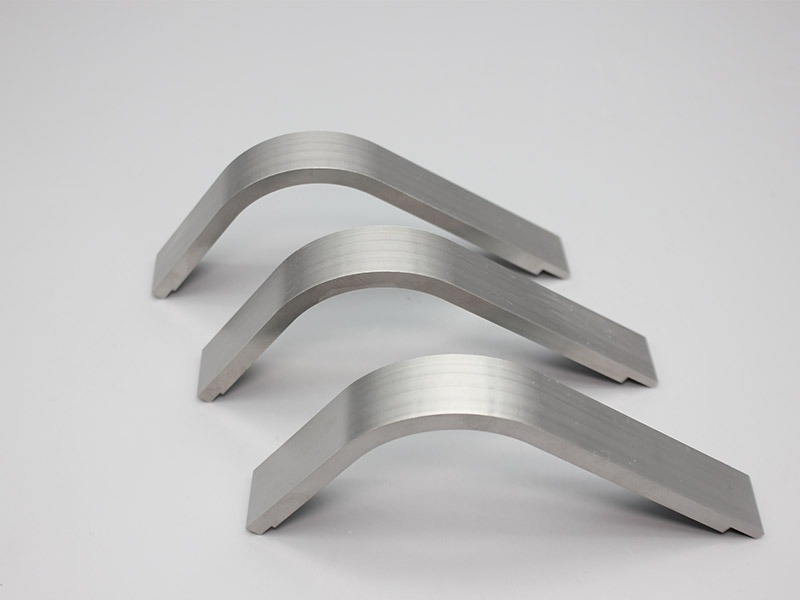

Tungsten alloy pin is a precision mechanical component made of tungsten - nickel - iron (W - Ni - Fe) or tungsten - nickel - copper (W - Ni - Cu) alloy (tungsten content 90% - 97%) or tungsten carbide (WC - Co), which is used for positioning, connection, transmission, and counterweight in various high - load, high - precision, and harsh - environment scenarios. It outperforms traditional steel and brass pins with its high density, high strength, wear resistance, and environmental protection.

Core Material & Performance

|

Property |

Tungsten Alloy (W - Ni - Fe/Cu) |

Tungsten Carbide (WC - Co) |

Steel Pin |

|

Density (g/cm³) |

16.5-18.5 |

14.5-15.6 |

7.85 |

|

Hardness |

HRC 45-55 |

HRA 88-92 |

HRC 20-30 (unhardened) |

|

High - Temp Resistance |

Maintains 70% strength at 800°C |

Stable at 1000°C+ |

Softens above 500°C |

|

Corrosion Resistance |

Good (no rust in general environments) |

Excellent (resists most chemicals) |

Poor (needs plating) |

|

Machinability |

Good (drilling, tapping available) |

Poor (brittle, needs diamond tools) |

Excellent |

|

Environmental Friendliness |

Non - toxic (lead - free), RoHS compliant |

Non - toxic |

Compliant |

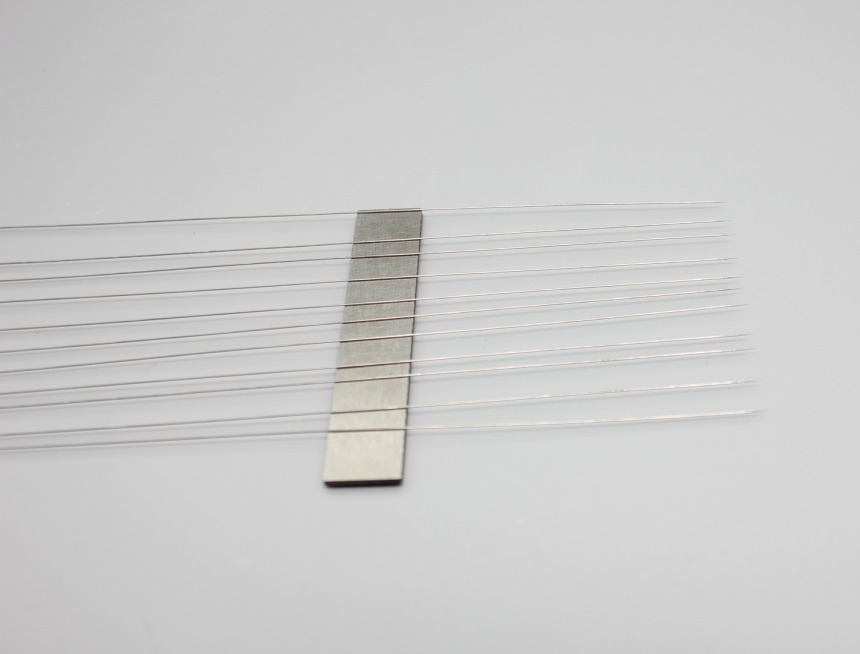

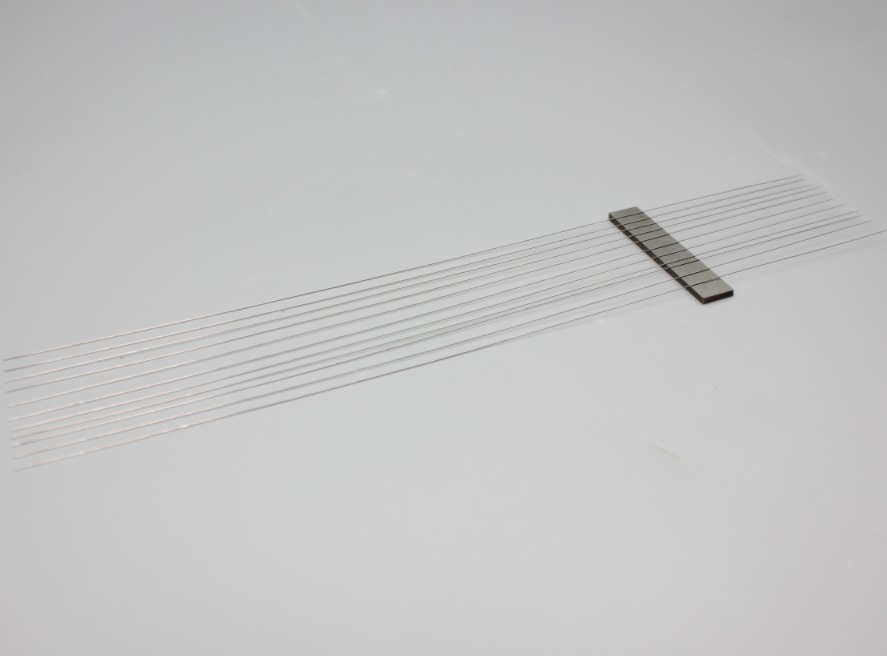

Electronics and industry: tungsten pin has high melting point and good conductance performance, and can be well used as electrode material, lead material, heater or gate in semiconductors, optoelectronics and vacuum electronic devices. According to the different uses of electronic test, pins can be divided into microelectronic test pins and optical circuit board test pins, respectively.

Welding industry: tungsten pin has high melting temperature and excellent corrosion resistance, and can be well used as an electrode material for argon arc welding and high temperature welding. In the argon arc welding process, the tungsten pin needs fine grinding, using the principle of tip discharge, play an arc role. Pin tube, a very important process material, plays a very important role in the development of modern industry.

Overall, tungsten alloy pins/wire are a versatile and reliable component for applications in a wide range of industries and applications.

Tungsten wire Tungsten alloy

EN

EN AR

AR FR

FR DE

DE HI

HI IT

IT JA

JA KO

KO PT

PT RU

RU ES

ES ID

ID LV

LV VI

VI HU

HU MS

MS GA

GA BE

BE YI

YI EU

EU